Technological Innovation and R&D

Innovation Philosophy

GCS always regards technological innovation as the core driving force for the development of the enterprise.

We are committed to providing our customers with more efficient, reliable, and environmentally friendly conveying equipment solutions through continuous technological research and development.

Our innovative philosophy is not only reflected in our products but also integrated into our corporate culture and daily operations.

Technical Achievements

Here are some of GCS technical achievements in recent years:

New Type of Environmentally Friendly and Energy-Saving Conveyor Roller

Utilizing advanced materials and designs to significantly reduce energy consumption and noise, and extend service life.

Intelligent Monitoring System

Integrated with sensors and data analysis technology to achieve real-time monitoring and fault prediction of conveying roller

Modular Design

Enhances the flexibility and scalability of the conveyor roller, reducing maintenance costs.

R&D Team

GCS technical team is composed of industry veterans and promising young engineers, who possess rich industry experience and a spirit of innovation.Team members continuously learn about the latest industry technologies and participate in domestic and international technical exchanges to ensure that our technology is always at the forefront of the industry.

R&D Cooperation

GCS actively establishes cooperative relationships with domestic and foreign universities, research institutions, and leading enterprises in the industry to jointly carry out technological research and development projects. Through these cooperations, we can quickly transform the latest scientific research results into practical industrial applications.

Future Outlook

Looking ahead, GCS will continue to increase investment in R&D, explore more innovative technologies, such as the application of artificial intelligence and the Internet of Things in the field of conveying equipment.

Our goal is to become a technological leader in the conveying equipment industry, providing global customers with more intelligent and automated solutions.

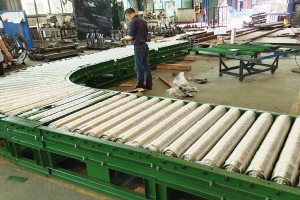

Manufacturing Capabilities

QUALITY CRAFTSMANSHIP FOR OVER 45 YEARS

Since 1995, GCS has been engineering and manufacturing bulk material conveyor equipment of the highest quality. Our state-of-the-art fabrication center, in combination with our highly trained employees and an excellence in engineering has created a seamless production of GCS equipment. The GCS engineering department is in close proximity to our Fabrication Center, meaning our drafters and engineers work hand in hand with our craftsmen. And with the average tenureship at GCS being 20 years, our equipment has been crafted by these same hands for decades.

IN-HOUSE CAPABILITIES

Because our state-of-the-art fabrication facility is equipped with the latest equipment and technologies, and is operated by highly trained welders, machinists, pipefitters, and fabricators, we are able to push out high quality work at high capacities.

Plant Area: 20,000+㎡

Equipment

Equipment

Equipment

Material Handling: Twenty (20) Traveling overhead cranes up to 15-ton capacity,Five (5) power liftfork up to 10-ton capacity

Key Machine: GCS provides various different types of cutting,welding services,allowing for a tremendous amount of versatility:

Cutting:Laser cutting machine(Germany Messer)

Shearing:Hydraulic CNC Front Feed Shearing Machine(Max thickness=20mm)

Welding:Automatic welding robot(ABB)(Housing, Flange Processing)

Equipment

Equipment

Equipment

Fabrication: Since 1995, the skilled hands and technical expertise of our people at GCS have been servicing the specialized needs of our customers. We have built a reputation for quality, accuracy and service.

Welding: Over four (4) welding machines Robot.

Certified for specialty materials such as: mild steel,stainless,carton steel,galvanized Steel.

Finishing & Painting: Epoxy, Coatings,Urethane,Polyurethane

Standards & Certifications: QAC , UDEM , CQC