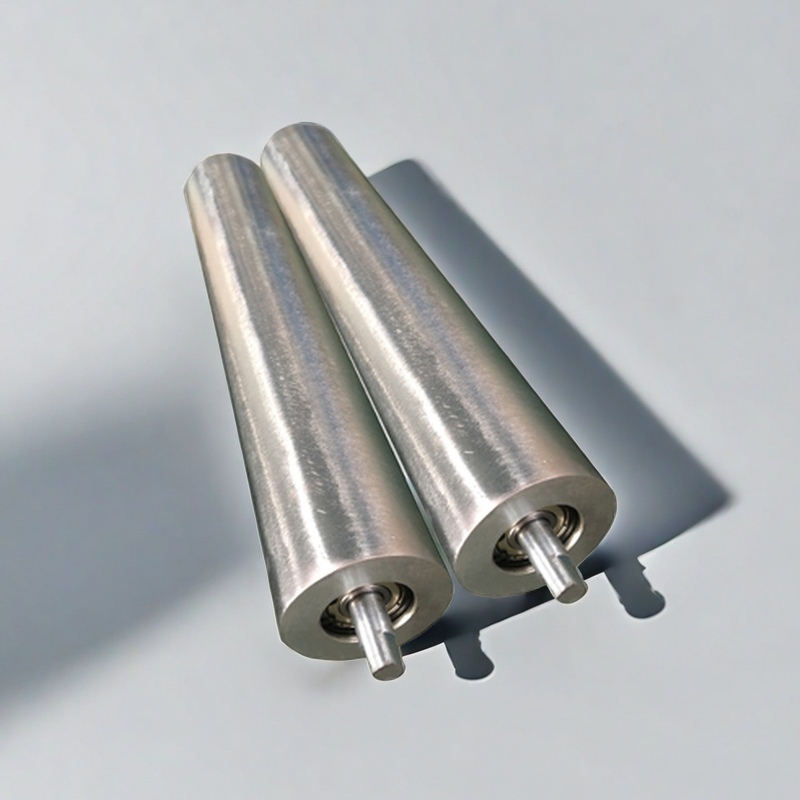

Tapered Conveyor Rollers

Tapered rollers have an outer diameter that is larger than the inner diameter. These rollers are used in a conveyor system's curved sections to maintain the material's position as its path turns. Installing tapered conveyor rollers delivers directional package handling without using side guards. Rollers with multiple grooves are for motorized and line shaft conveyor systems.

Tapered conveyor rollers are a key component in creating smooth and efficient conveyor systems, especially for applications requiring precise direction control, such as curves in conveyor tracks. With years of expertise in manufacturing, GCS pride ourselves on delivering products that combine innovation, durability, and exceptional performance.

MODELS

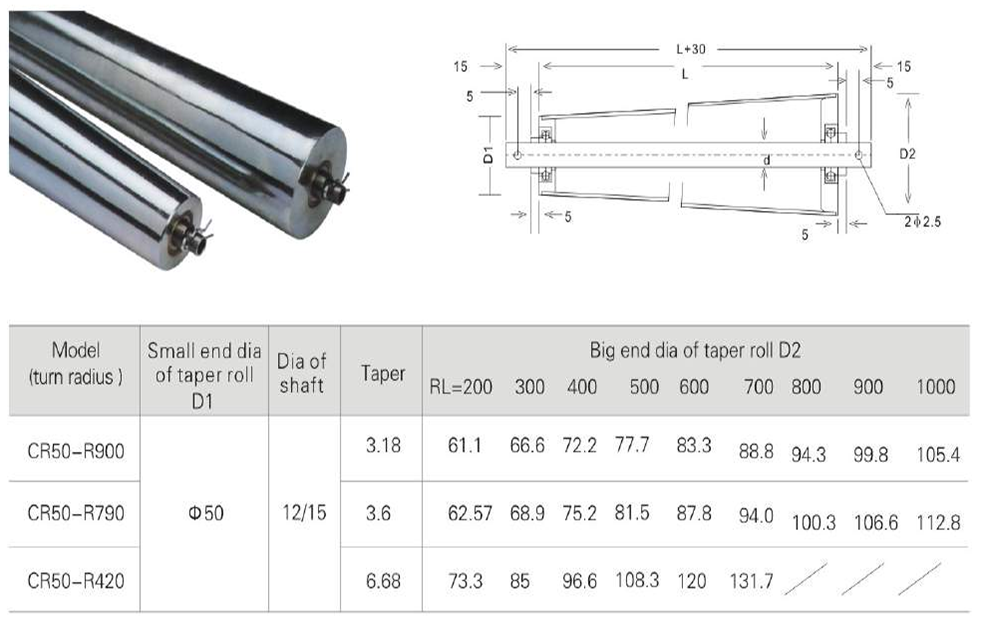

Cone Roller

● Designed to facilitate the smooth transfer of goods, especially for products with irregular shapes or varying sizes.

● A conical shape, which helps to improve the stability and guiding of materials, reducing the risk of product slippage during transport.

● Made with high-quality materials to withstand heavy-duty use and provide long-term performance.

● Used in conveyors, storage systems, and assembly lines for both light and heavy goods.

● Offers customizable Options.

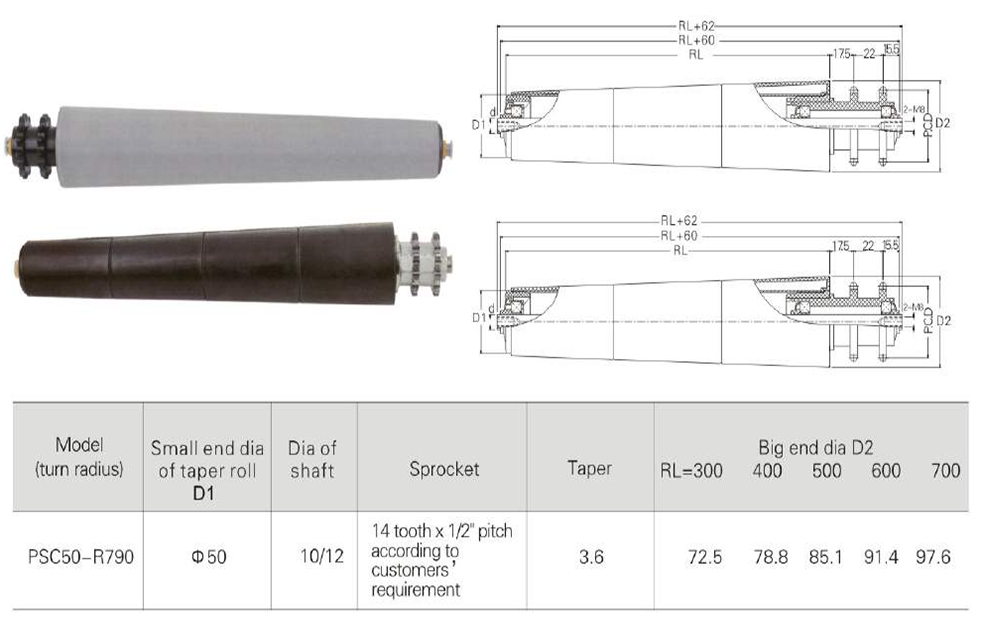

Plastic Sleeve Sprocket Roller

● GCS plastic sleeve covering provides enhanced resistance to rust and corrosion, making these sprocket rollers ideal for use in harsh environments, including those exposed to moisture or chemicals.

● Lighter than traditional metal sprockets, making them easier to handle, install, and maintain.

● Allows for reduced friction and wear, ensuring that the roller operates efficiently with minimal maintenance.

● Plastic sleeve provides better traction, improving the grip between the sprocket and chain.

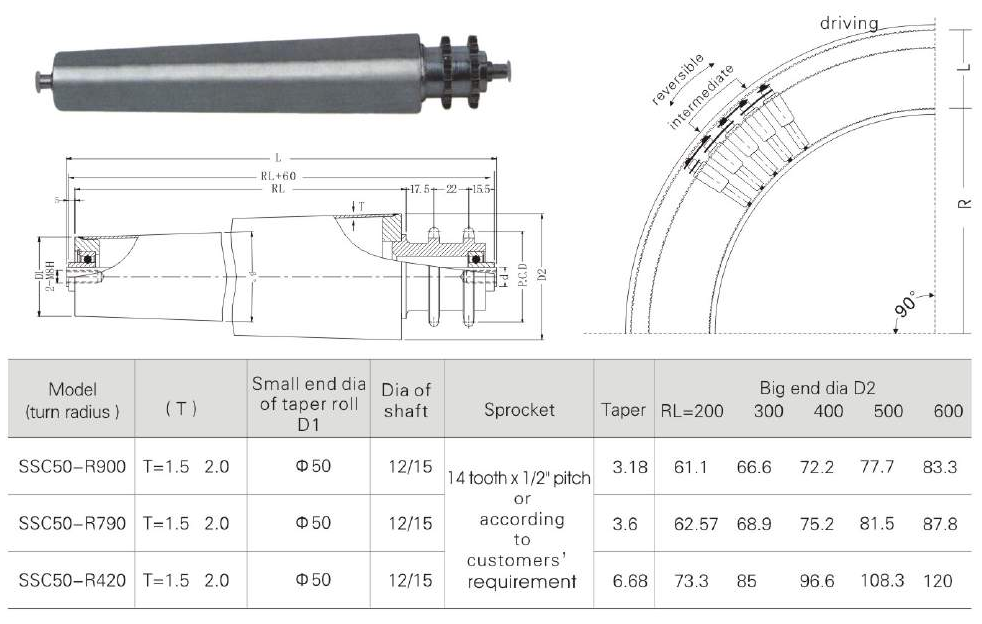

Double Sprocket Curve Roller

● Ensures a more secure and stable connection between the roller and chain

● Specifically designed for use in curved conveyor tracks

● Distribute the load more evenly

● Minimizes friction between the sprockets and the chain

● Last resistance to wear, corrosion, and other environmental factors

● Provides more precise control over the movement of products

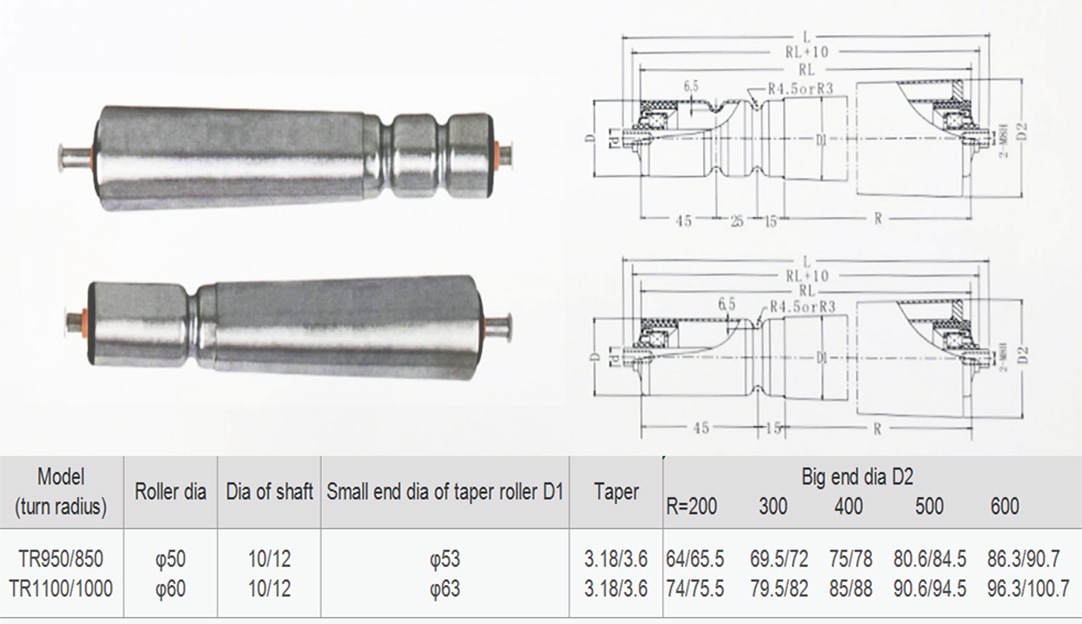

Singles/Double Groove Cone Roller

● Enhances the roller's ability to securely guide and support products.

● Ideal for various types of conveyors.

● Improve the grip between the roller and the product.

● Allows for smoother transitions and helps guide products with precision.

● Provides extra support and stability for handling heavier or larger items.

● Quieter operation by reducing friction and wear

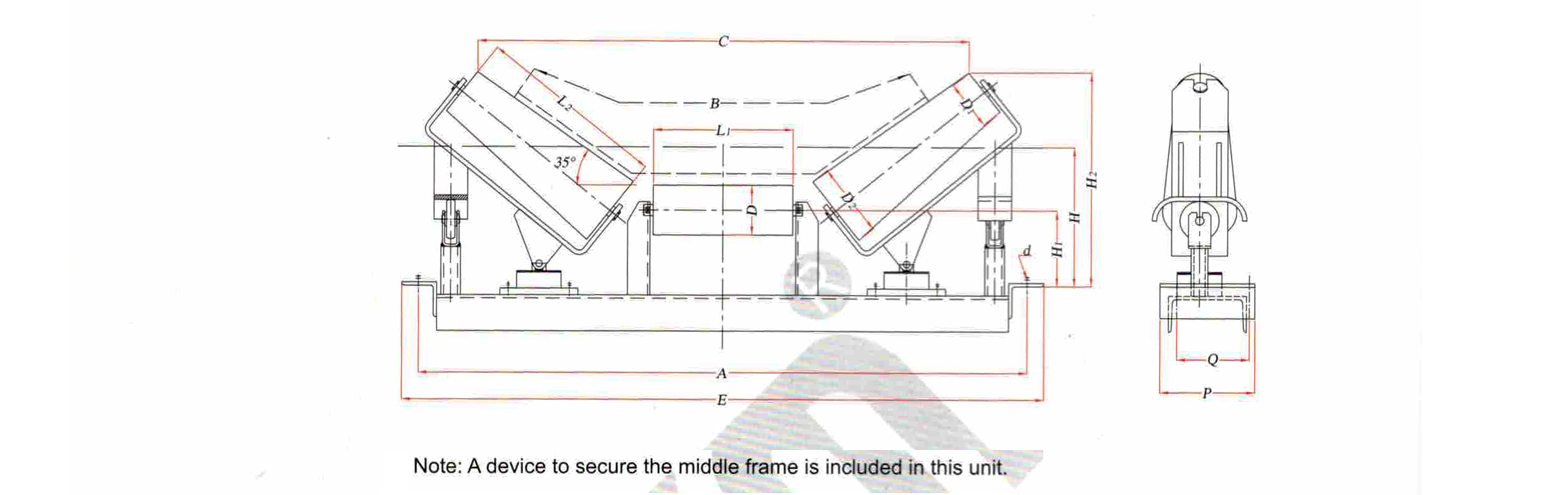

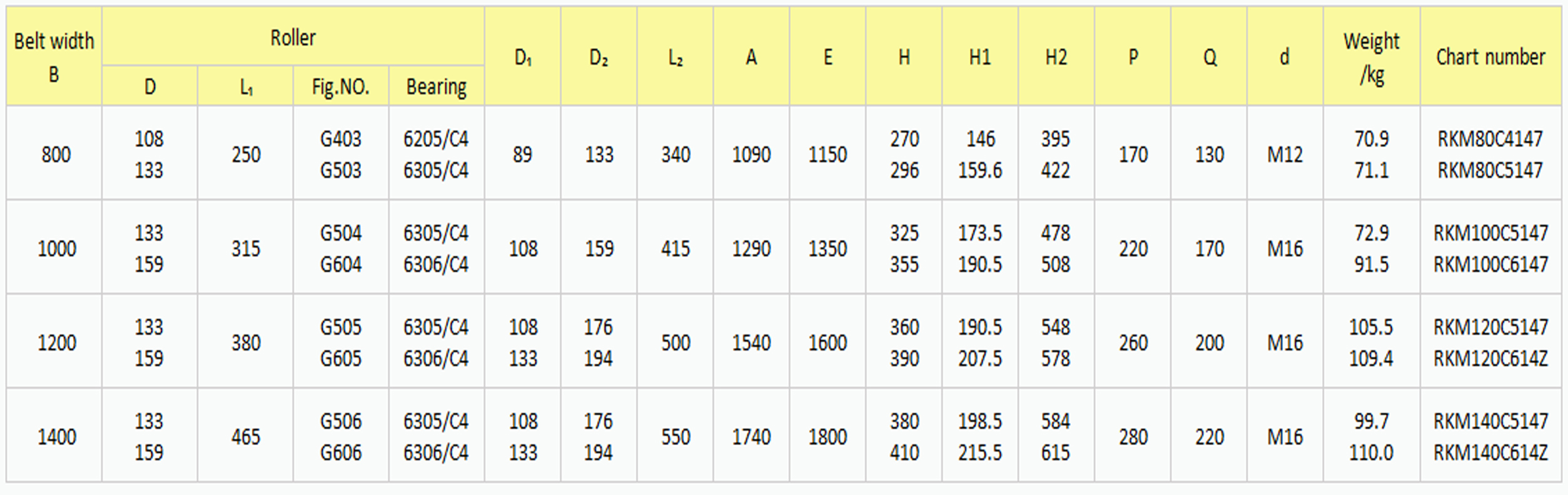

Conical Upper-Aligning Roller Set

Built with 3 rollers, normally on conveyor belts with belt width of 800mm and above. Both sides of the rollersare conical. Diameters (mm) of the rollers are 108, 133, 159 (also available is the larger diameter of 176,194) etc. The usual trough angle is 35°and normally every 10th trough roller set will be fitted with an aligning roller set. Installation is on the load bearing section of the conveyor belt. Its purpose is to adjust any deviation of the rubber belt from both sides of the center line whilst lining the conveyor belt machine to maintain the correct deviation and ensure the conveyor belt machine operates smoothly. It is normally used for conveying light duty materials.

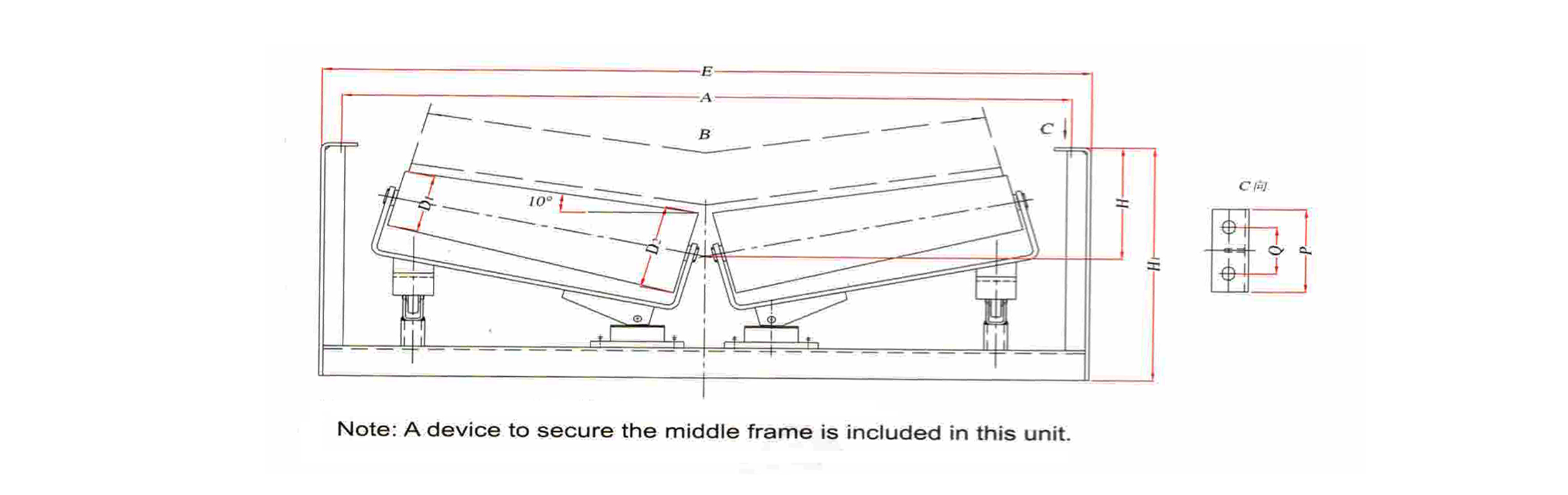

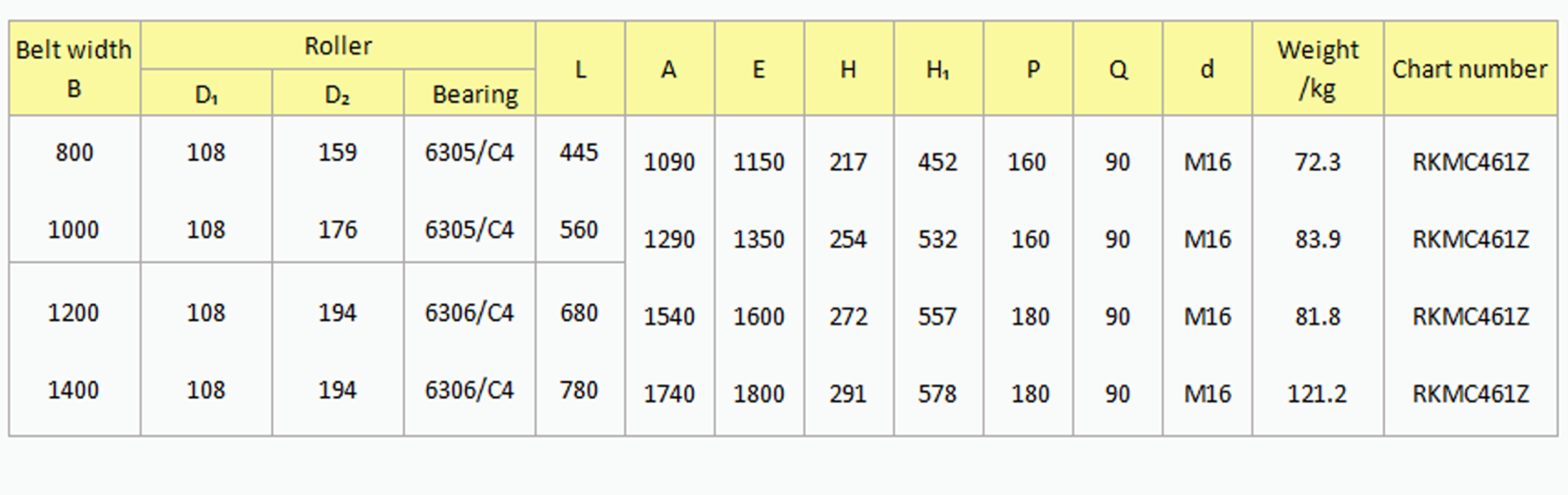

Conical Lower Aligning Roller Set

Built with 2 conical rollers: small end roll with diameter of 108mm and large end roll with diameter (mm) of 159, 176,194 etc. Normally every 4-5 lower roller sets will require 1 aligning roller set. This is suitable for conveyor belt width 800mm and above. Installation is on the return section of the conveyor belt. Its purpose is to adjust any deviation of the rubber belt from both sides of the center line, to maintain the correct deviation and ensure the conveyor belt machine is maintained in proper condition and operating smoothly.

Photos & Videos

Materials & Customization Options

Material Choices of Tapered Conveyor Roller:

Carbon Steel: Suitable for general industrial applications, offering high load capacity and abrasion resistance.

Stainless Steel: Ideal for environments requiring enhanced corrosion resistance, such as food, chemical, and pharmaceutical industries.

Aluminum Alloy: Lightweight, perfect for light-duty conveyor systems.

Hot-Dip Galvanized Steel: Additional corrosion protection, ideal for outdoor or high-humidity environments.

Polyurethane Coating: Suitable for heavy-duty and high-wear applications, especially in bulk handling systems.

Customization Services of Tapered Conveyor Roller:

Size Customization: We offer comprehensive customization from diameter to length, based on your specific conveyor system requirements.

Special Coatings: Options such as galvanizing, powder coating, and anti-corrosion treatments to meet various environmental needs.

Special Components: Different types of bearings, seals, and other accessories to ensure rollers are perfectly suited to your conveyor system.

Surface Treatment: Various surface treatment options, including plating, painting, or sandblasting, to enhance corrosion resistance and aesthetic appeal.

Load and Capacity Customization: For higher load requirements, we can supply rollers designed to handle larger weights, ensuring long-term reliable performance of your system.

One-on-One Service

Since customized conveyor tapered rollers are engineered precisely, we kindly request that you consult with one of our technical experts to ensure we provide the best solution tailored to your specific needs.

Let us know your needs: specifications/drawings

After collecting the usage requirements, we will evaluate

Provide reasonable cost estimations and details

Draft technical drawings and confirm process details

Orders are placed and generated

Products delivery to customers and after-sales

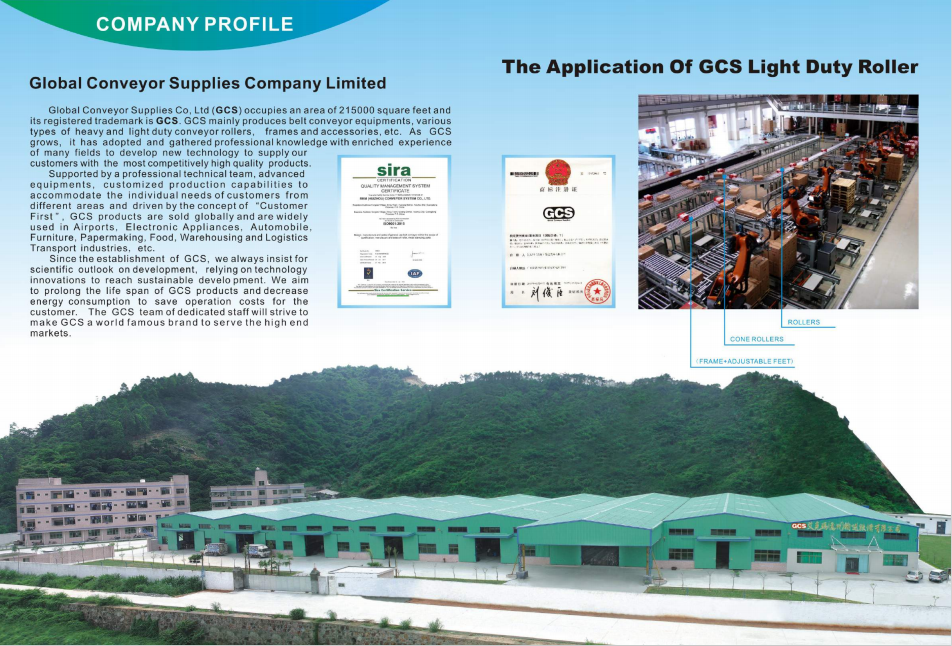

Why Choose GCS?

Extensive Experience: With years of industry experience, we deeply understand your needs and challenges.

Customization Services: Offering tailored solutions to meet various requirements.

Fast Delivery: Efficient production and logistics systems ensure timely delivery.

Technical Support: We provide comprehensive after-sales support and technical consultation services to ensure the smooth operation of your equipment.

For a more efficient and automated solution, check out our Motorized Drive Roller!

Contact GCS Today to Learn More

Finding the perfect roller for your operation is crucial, and you want to do so with little disruption to your workflow. If you need a special-size roller for your conveyor system or have questions about the rollers’ differences, we can assist you. Our customer service team can help you get the right part for your existing conveyor system.

Whether installing a new system or needing a single replacement part, finding suitable rollers can improve your workflow and increase your system’s life. We will help you get the right part with fast communication and personalized care. To learn more about our rollers and custom solutions, contact us online to speak with a specialist or request a quote for your roller needs.

Frequently Asked Questions

What is a tapered conveyor roller, and how does it differ from a standard roller?

· A tapered conveyor roller has a conical shape, where the diameter decreases from one end to the other.

What materials are used to manufacture tapered conveyor rollers?

· Tapered conveyor rollers can be made from a variety of materials, including carbon steel, stainless steel, aluminum, and galvanized steel.

Can you customize the size and specifications of the tapered conveyor rollers?

· Yes, we offer full customization of tapered conveyor rollers, including diameter, length, material, and special coatings.

What is the maximum load capacity of your tapered conveyor rollers?

· The load capacity of tapered conveyor rollers depends on the material, size, and design of the roller. We can provide rollers with varying load capacities tailored to your specific needs, from light-duty applications to heavy-duty operations.

What kind of maintenance do tapered conveyor rollers require?

· Tapered conveyor rollers generally require minimal maintenance. Regular cleaning to remove debris and periodic lubrication of bearings are the main maintenance tasks.