Powered Conveyor Roller

Powered conveyor rollers take less effort to move loads than unpowered (gravity-flow) conveyor rollers. They convey items at a controlled speed with even spacing. Each conveyor section consists of rollers that are mounted on a series of axles attached to a frame. A motor-driven belt, chain, or shaft turns the rollers, so these conveyors do not require a manual push or slope to move loads down the line. The powered conveyor rollers provide a stable surface for moving loads with rimmed or uneven bottoms, such as drums, pails, pallets, skids, and bags. Loads roll forward along the conveyor, and they can be pushed from side to side across the width of the conveyor. The conveyor's roller spacing density affects the size of the items that can be conveyed on it. The smallest item on the conveyor should be supported by at least three rollers at all times.

Unlike Non-Drive gravity rollers, powered conveyor rollers provide consistent and controlled motion, making them ideal for applications requiring higher efficiency, automation, and precision. These rollers are commonly used in industries like logistics, manufacturing, and distribution to transport goods, packages, or materials smoothly and efficiently across various distances.

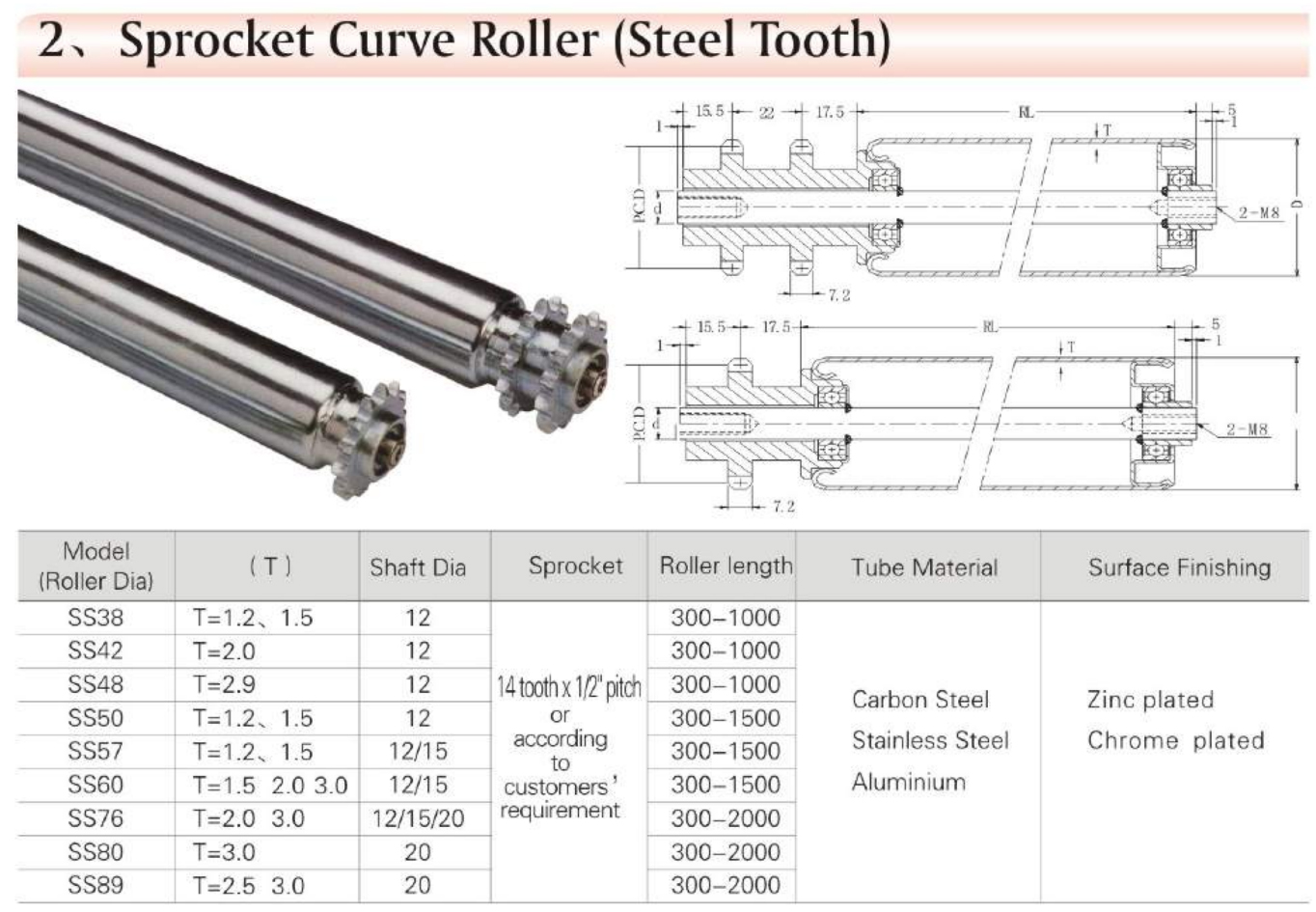

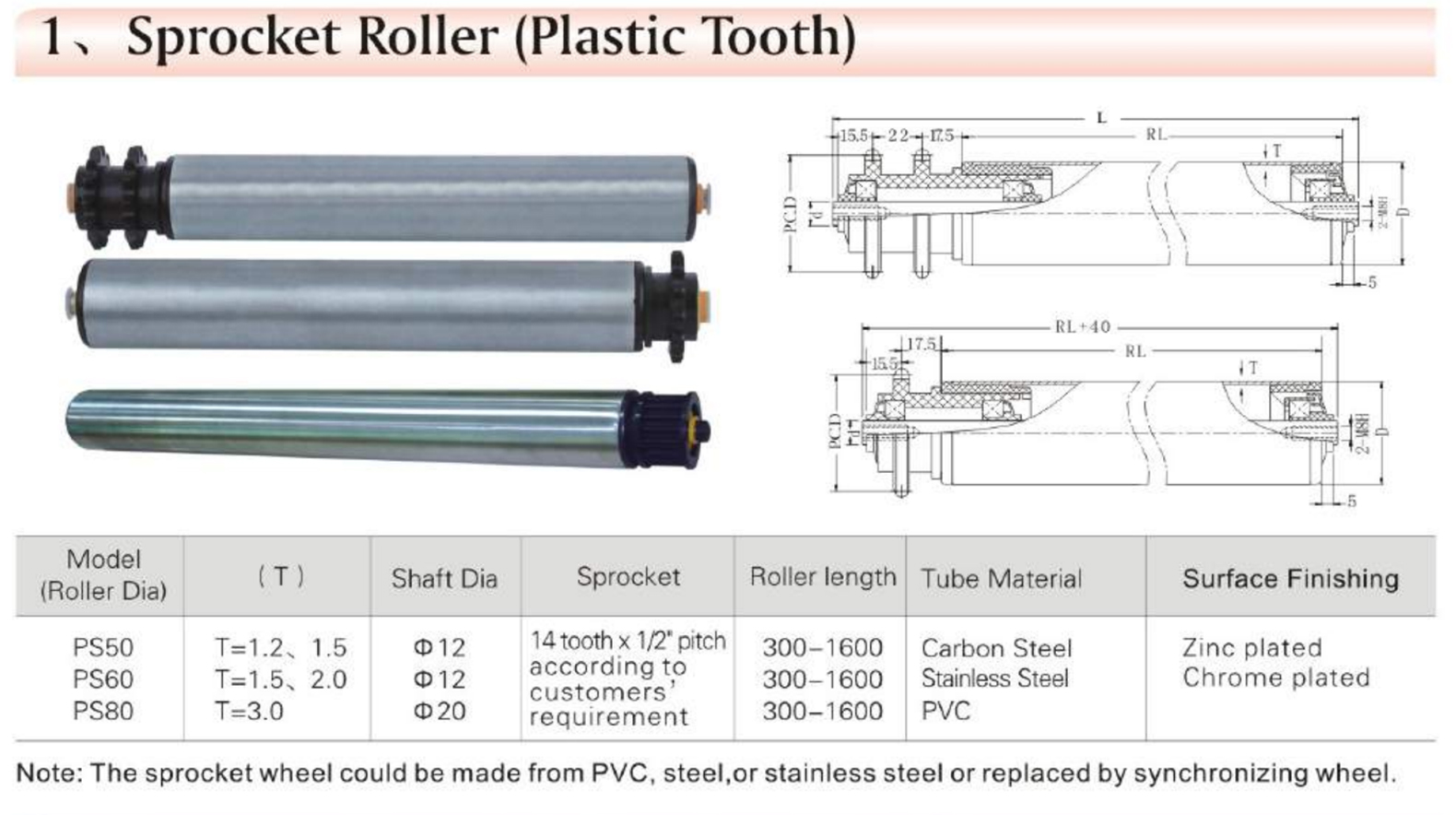

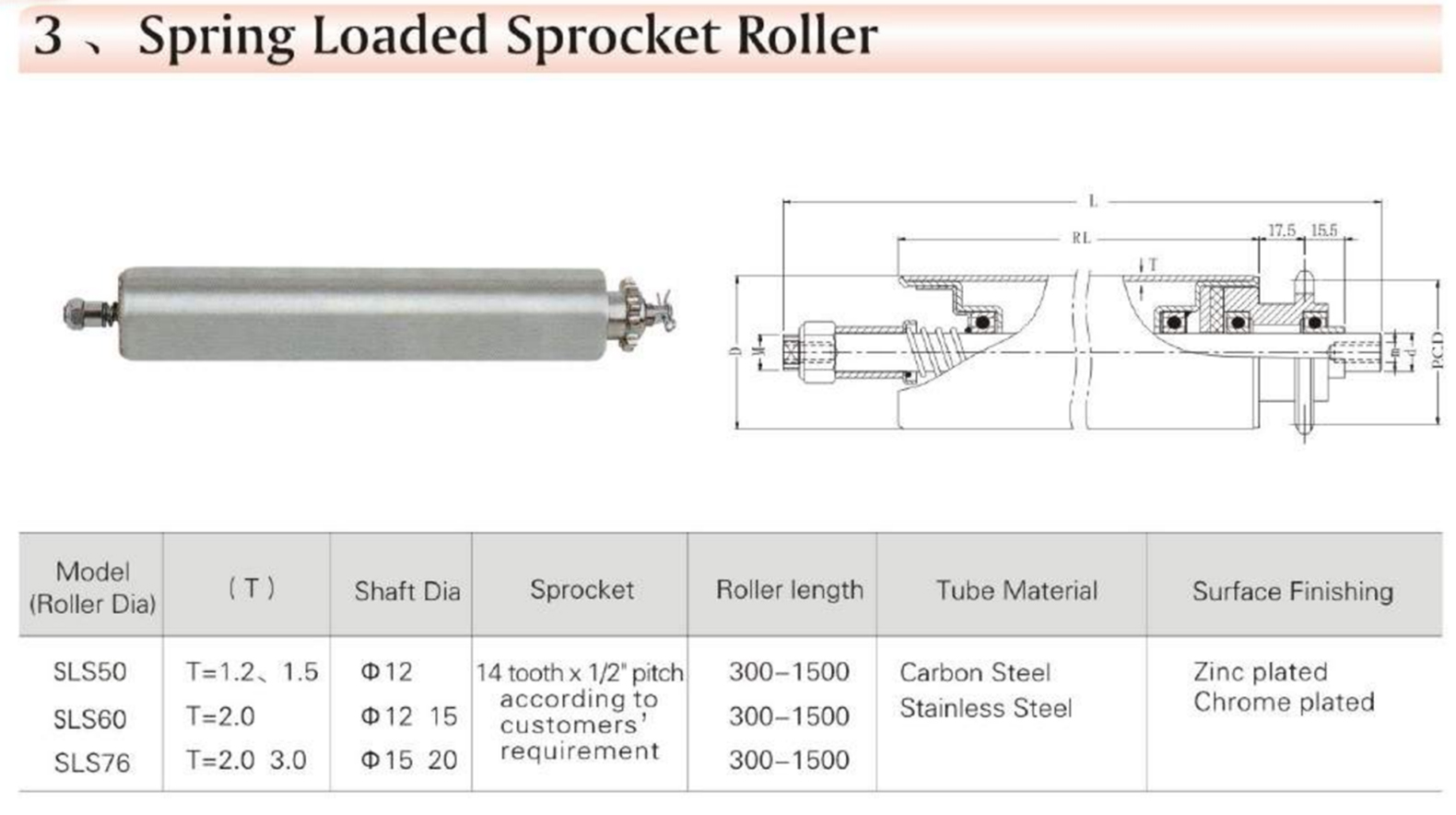

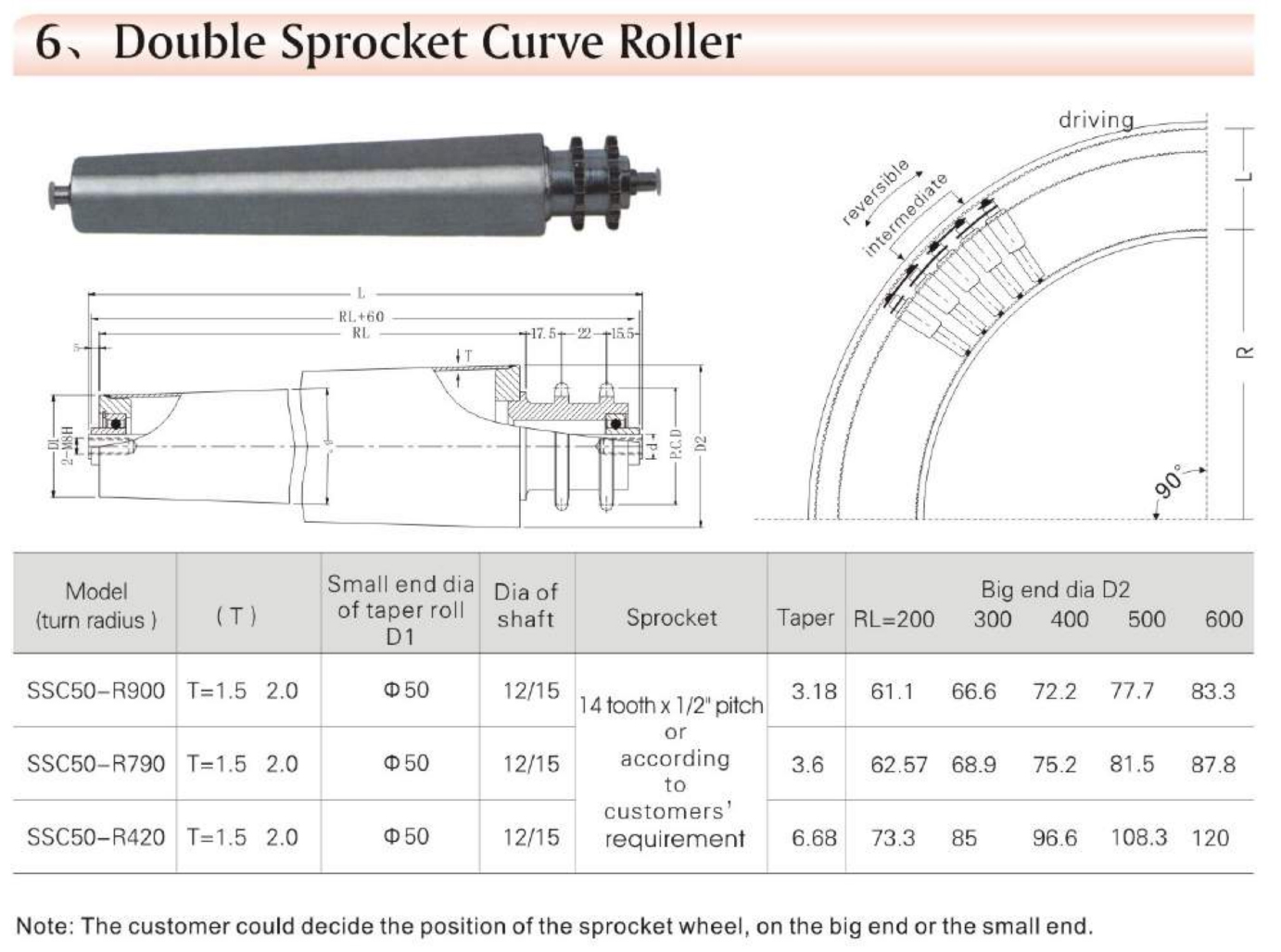

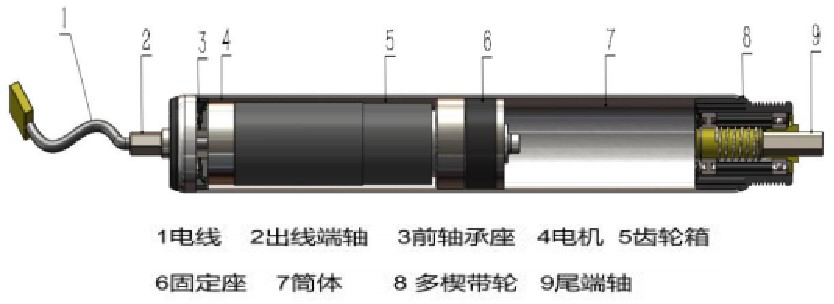

◆ Types of Powered Conveyor Roller

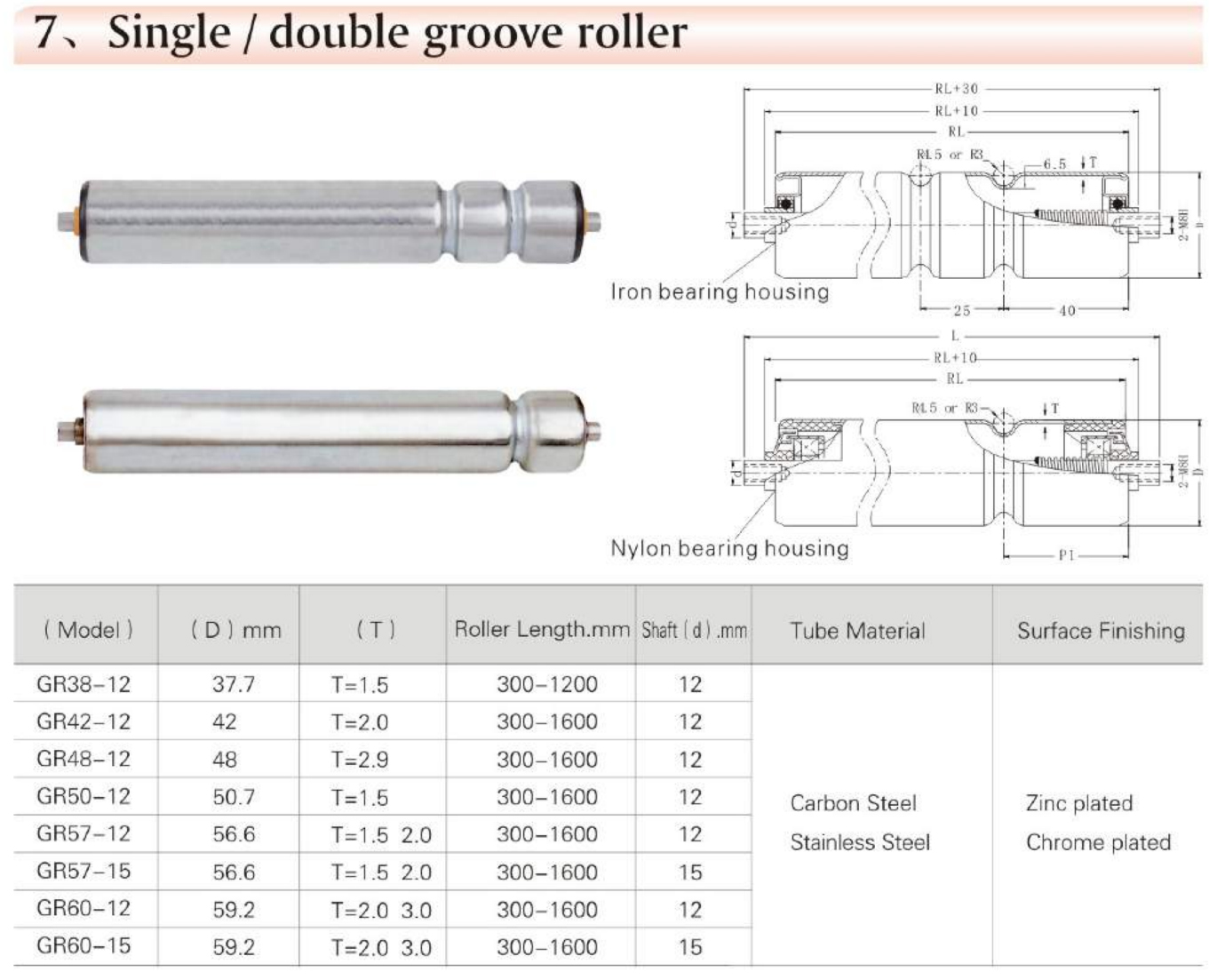

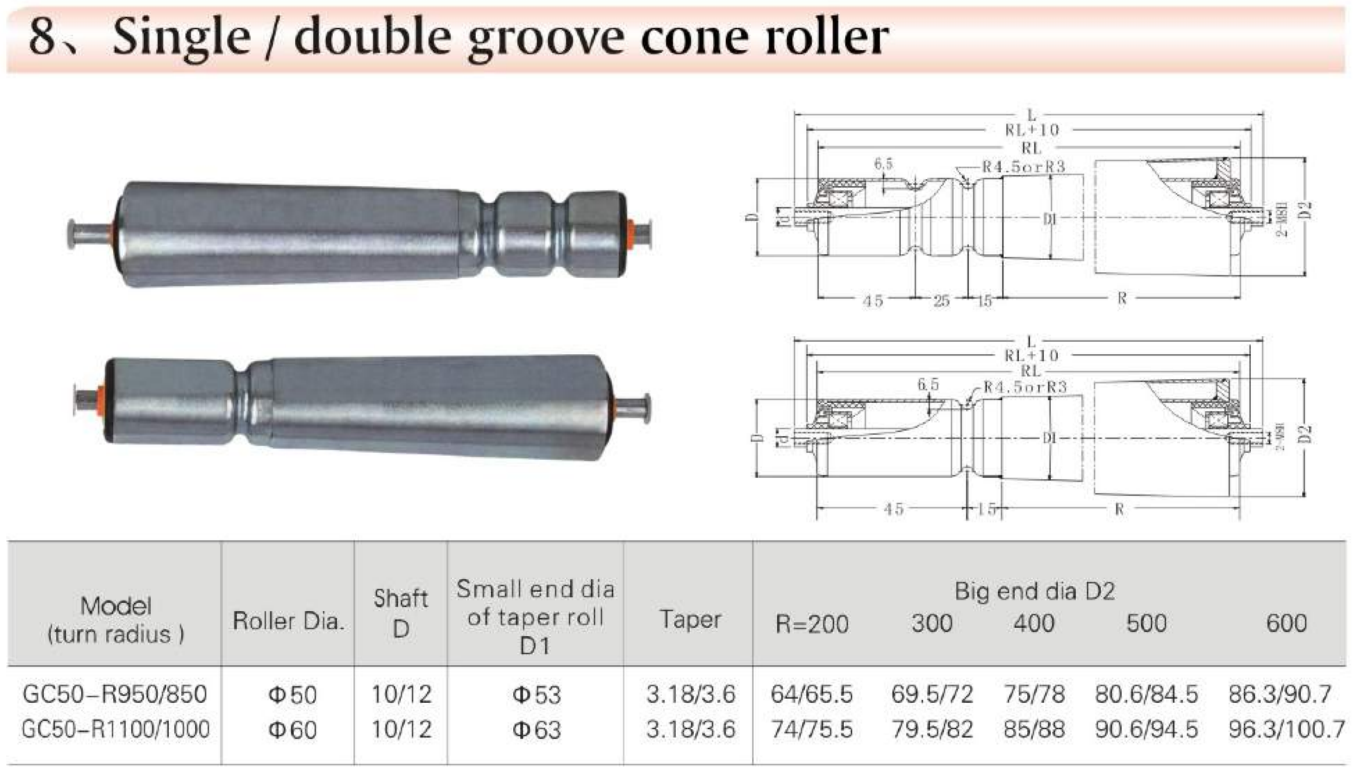

Specification and Technical Data

Pipe: Steel; Stainless Steel (SUS304#)

Diameter: Φ50MM---Φ76MM

Length: Customized Cable

Length: 1000MM

Power Plug: DC+、 DC-

Voltage: DC 24V/48V

Rated Power: 80W

Rated Current: 2.0A

Working Temperature: -5℃ ~ +60 ℃

Humidity: 30-90%RH

Features of Motorized Conveyor Roller

Japan NMB Bearing

STMicroelectronics Control Chip

Automotive Grade MOSFET Controller

Advantages of Motorized Conveyor Roller

High Stability

High Efficiency

High Reliability

Low Noise

Low Failure Rate

Heat Resistance (Up to 60。C)

◆ Materials and Manufacturing Process

1. Materials

To ensure the long-term stability and high load-bearing capacity of the powered conveyor rollers, we use high-strength materials that meet the demands of various working environments:

Steel: We use high-strength carbon steel or alloy steel, which offers a higher load-bearing capacity, making it ideal for heavy-duty applications and continuous operation. Steel provides excellent compressive strength and wear resistance, making it well-suited for high-load conditions.

Aluminum Alloy: Our lightweight aluminum alloy rollers have a lower coefficient of friction and superior corrosion resistance, making them ideal for lighter loads or applications where reducing equipment weight is a priority.

Stainless Steel: For environments that require high corrosion resistance (such as food processing, chemical industries, etc.), we offer stainless steel rollers. These powered conveyor rollers can withstand harsh environments and provide excellent oxidation resistance.

Each material selection is made with great care to ensure that the rollers not only handle everyday operational loads but also adapt to different environmental conditions.

2. Bearings and Shafts

We use high-precision ABEC bearings and high-strength shaft materials to ensure the stability and durability of the rollers during long-term operation. These bearings undergo strict quality control to withstand high loads and high-speed operations, minimizing wear and preventing failures.

3. Manufacturing Process

All rollers are manufactured using precision machining techniques, including CNC cutting and automated welding. These advanced processes not only enhance production efficiency but also ensure the consistency and accuracy of each roller. Our production line strictly adheres to international standards, with rigorous quality control at every stage—from raw material procurement to final product shipment.

◆ Customization Services

We understand that each customer's needs are unique, which is why we offer comprehensive customization services:

Size Customization: We can customize the length and diameter of the rollers according to the dimensions of your conveyor system.

Function Customization: Different drive methods, such as chain drive and belt drive, can be equipped.

Special Requirements: For special application scenarios, such as heavy-duty, high-temperature, or corrosive environments, we provide customized solutions.

◆ Core Advantages

Efficient Conveying: Our powered conveyor rollers feature advanced motor drive technology to achieve stable goods transportation, with adjustable speeds according to your needs. For example, our 24V powered rollers equipped with drive cards can realize highly efficient power transmission.

Durability: The products are manufactured with high-quality materials such as galvanized steel and stainless steel, ensuring long-term stable operation even in harsh environments.

Customization Services: We provide a wide range of customization options, including roller diameter, length, material, bearing type, and more, to meet your individual needs.

Easy Maintenance: The simple design makes maintenance easy, reducing downtime and improving production efficiency.

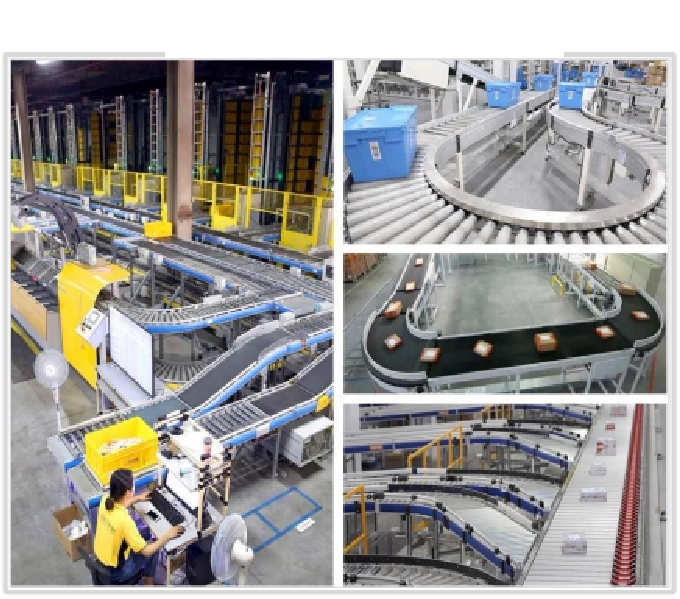

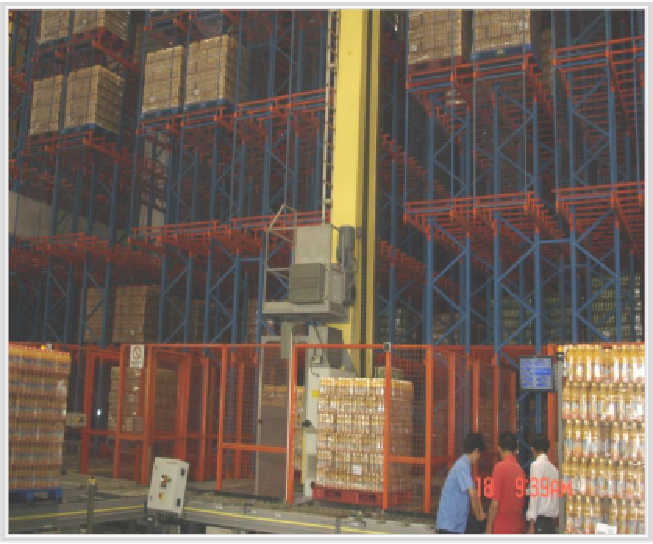

◆ Powered Conveyor Roller in Actions

Logistics and Warehousing

In the logistics and warehousing industry, our powered conveyor rollers are widely used for the rapid sorting and handling of goods. They can help you enhance logistics efficiency, reduce labor costs, and ensure the safety of goods during transportation.

Manufacturing

In the manufacturing sector, powered conveyor rollers are an essential part of the production line. They can achieve automated material handling, minimize manual intervention, and improve production efficiency and product quality. Whether in automotive manufacturing, electronics production, or mechanical processing, our powered conveyor rollers can provide you with reliable solutions.

Food Processing

In the food processing industry, hygiene and safety are of utmost importance. Our stainless-steel powered conveyor rollers fully comply with the hygiene standards of the food processing industry, ensuring the safety and hygiene of food during processing. At the same time, their efficient conveying performance can meet the strict requirements of food processing production lines.

Agriculture

In the agricultural sector, powered conveyor rollers can be used for the handling and packaging of agricultural products. They can help you increase agricultural production efficiency, reduce labor intensity, and ensure the integrity and freshness of agricultural products during transportation.

◆ Productiviy Solution of Powered Conveyor Roller

Pre-sales Service

Professional R&D team: Provide turnkey automation solutions for project inquiry

Site Service

Professional Installation Team: Provide on-site installation and commissioning service

After-sales Service

After-sales Support Team: 24-hour Service Hotline Door to Door solutions

GCS is supported by a leadership team who have decades of experience in operation of conveyor manufacturing company, a specialist team in conveyor industry and general industry, and a team of key employee who are essential for assembly plant. This helps us understand our customers' needs for productivity solution better. If you need a complex industrial automation solution, we can do it. But sometimes simpler solutions, such as gravity conveyors or power roller conveyors, are better. Either way, you can trust our team’s ability to provide the optimal solution for industrial conveyors and automation solutions.

Can GCS provide me with a rough budget for my powered conveyor rollers?

Of course! Our team works every day with customers who purchase their first conveyor system. We'll help you through the process, and if appropriate, we'd often prefer to see you start using a low-cost "fast shipping" model from our online store. If you have a layout or a rough idea of your needs, we can give you a rough budget. Some customers have sent us CAD drawings of their ideas, others sketched them on napkins.

What exactly is the product you want to move?

How much do they weigh? What is the lightest? What is the heaviest?

How many products are on the conveyor belt at the same time?

How big is the minimum and maximum product that the conveyor will carry (we need length, width and height)?

What does the conveyor surface look like?

This is really important. If it is a flat or rigid carton, tote bag, or pallet, it is simple. But many products are flexible or have protruding surfaces on the surfaces where the conveyor carries them.

Are your products fragile? No problem, we have a solution

Frequently asked questions about powered conveyor rollers

What is the maximum load capacity of your powered conveyor rollers?

Our powered conveyor rollers are designed to handle a wide range of load capacities depending on the size and material of the roller. They can support loads from light-duty applications (up to 50 kg per roller) to heavy-duty ones (up to several hundred kilograms per roller).

What industries are your powered conveyor rollers suitable for?

Our powered conveyor rollers are versatile and suitable for various industries, including logistics, manufacturing, automotive, food and beverage, pharmaceuticals, and warehousing.We can also customize the rollers to meet the specific needs of your industry.

Can your powered conveyor rollers be customized in terms of size, material, or surface finish?

Yes, we offer extensive customization options for our powered conveyor rollers. You can customize the roller diameter, length, material (steel, stainless steel, aluminum), and surface finish (e.g., powder coating, galvanizing) to suit your operational environment. If you have special requirements, we can work with you to create a tailored solution.

How easy are the powered conveyor rollers to install and maintain?

Our powered conveyor rollers are designed for easy installation and minimal maintenance. Installation is straightforward and can typically be done with basic tools. For maintenance, the rollers are designed for durability, and we offer support for any technical issues or spare parts as needed. Additionally, our motorized models often require less maintenance since they have fewer moving parts and no external transmission systems.

What is the expected lifespan of your powered conveyor rollers? Do you offer a warranty?

Our powered conveyor rollers are built to last, with a typical lifespan of 5–10 years depending on usage and environmental conditions. We offer a warranty for all our products to ensure customer satisfaction and peace of mind. Our team is also available for any technical support or maintenance needs throughout the lifespan of the rollers.